ONE MAN’S CRUSADE AGAINST A FAILING CEMENT PLANT Part II

Posted on July 29th, 2017

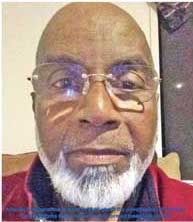

By Dr. Tilak S. Fernando

The heart of a cement plant is the grinding mill, says Ananda Karunarathne, where clinker is ground with gypsum (a soft white or gray mineral consisting of hydrated calcium sulfate) to manufacture cement. The original manufacturers of the mill at Galle had been Danish Company, and in today’s context, one would say it was a very conventional type and had three chambers with an output of 18 tons per hour. That meant grinding of weathered clinker was slow, yet the specific surface of the cement exceeded the set standards thus strengthening the output more than the expected norms or standards.

When Ananda Karunarathne made his maiden visit to the Galle factory on an inspection prior to taking over the factory the engineer, who was entrusted to look after the site, warned him not to touch the mixed stock of lime stone and clinker at the yard and stores with a warning that, ‘if you want to end your career here, you had better touch it’. This very statement made Ananda to take a tenacious decision to go for it. Finally the Corporation made Rs.7 million out of those written off clinker by introducing into the local market, which gave a tremendous boost to down south cement dealers as well as to the employees, who began to realize that ‘something was happening at the Galle Plant.”

Involved

Ananda Karunarthana’s efforts were rewarded with a cheque for Rs.100,000 by the Chairman of the Corporation, out of which 80 per cent of it he shared among his workers, who were really involved in achieving such results.

When he took over the Galle Cement Plant as the Manager, he observed the idling nature of the Galle Port too, where port labourers came in the morning, syndicated for a bottle of arrack and enjoyed their drink and went home! When things began to improve, head office staff and supervisors began to think it would be a viable entity to support and contribute as much as they could by signing for clinker deliveries to Galle port and deliveries.

The function of a seaport has to be efficient in discharging the cargo at a pace, without incurring any demurrages. To expedite this task Ananda introduced an incentive scheme to the port workers that really worked effectively to achieve set targets of unloading. During his first year in Galle, the production achieved 117,000 metric tons that was the highest since the inception of the plant. Previous highest record ever achieved was only 20, 000mt.

Mill modification

The heart of a cement plant is the grinding mill where clinker is crushed to produce cement. The mill at Galle had three chambers with steel grinding balls to crush the clinker into a powder form at the rate of 18 tons per hour, although the designed output was 20 tons per hour. Ananda Karunarathne having detected an old quotation from the original manufacturers, which was quite steep, wanted to modify three chambers into two, as he felt that he could do it with the help of the existing staff (he, being a mechanical engineer himself) considering the hassle involving in various forms of tender procedures where long drawn procedures were to adopt.

Lengthy discussions and studies took place and finally the green light was given to him to go ahead with the project with his own staff with the support extended by the Blue Circle Management team from the UK, who was in Sri Lanka at that time. In the modification process, the only spare part that needed to be imported was the diaphragm for the partition. The Sri Lankan technical support team did the rest of the work that brought a major breakthrough to the operation of the mill to increase the production by 60 per cent.

Quality Control Circles

Once, during a management meeting, at Colombo Headquarters, Sunil Wijesinghe, the then Chairman of the Employees’ Trust Fund (ETF) delivered an oration on Quality Control Concept and about QCCs (Quality Control Circles). At the end of the lecture, he discouraged the senior management not to emulate the Japanese system with a warning that there was a vast difference between Japanese and Sri Lankan way of manufacture. However, the General Manager K.V.H. Premachandra arranged Ananda to visit Malaysia on a study tour to observe and learn how ‘Circles’ in Malaysia really worked. His study tour was quite successful, the result being after several training sessions he managed to put up a couple of circles. At first, people viewed his attempts distrustfully, but once commenced and the establishment flourished with the QCC, it became a showpiece of Ruhunu Management System.

QCCs were established and practised in Japan initially and followed by many in most of the countries, particularly in Asia seemingly. Ananda Karunarathne was therefore able to attend world conventions as well as to nominate a few groups of his employees, which really boosted the morale of the staff. In the meanwhile, the adoption of QCCs went to many other working environments, consequent of which many establishments contacted Ananda Karunarathne with invitations to promote this concept in their works. Although it was a great effort to organise and coordinate and stage the first ever QCC Convention by any enterprise in Sri Lanka, Ananda Karunarthane’s efforts ended up as a great success. Subsequently, Ananda Karunarathne held the position of the Vice President of the Quality Control Circles Association of Sri Lanka (QCCASL). Finally the Ruhunu Plant became a model and a research centre for some of the MBA students from the Post Graduate Institute

Living example

The Ruhunu Plant was referred to as a living example of ‘Worker-Management Corporation’ because what people normally get to hear about government corporations is only loss making liabilities! Why does any institution tend to make losses, it is because only due to shortcomings between the management and the operational techniques. Therefore, it becomes the prime duty of the officials to look into those areas where there are flaws. Having targets to achieve could be considered as the prime aim of completing any production or rendering any service effectively. In this context motivation of workers towards such targets play a prominent role. On the other hand, having targets alone will not perform miracles, but it will become necessary to form working committees to monitor performance levels on a daily, weekly and monthly intervals.

Galle Cement Factory in this context had proved as a typical example in a highly profitable institution, much of the credit given to the new General Manager, who was able to wave his magic wand and helped to improve not only the attendance of the workers but enhanced the production too with discipline. Galle Cement Plant operation was viewed at the time as a sample to emulate by other corporations.

Once, Ananda Karunarathne spotted someone seated in his veranda of his official residence. It was none other than the late Dr. W. Dahanayake, who was the then Minister for Co-operatives. In his usual charming manner Dr. Dhahanayake’s visit had been purely to compliment Ananda for transforming the Galle Cement Plant towards a viable and one of the best entities in the island.

Five years later Ananda was asked to take over the Puttlam Plant. He accepted the challenge and, according to him, it was another long story. Under two years of his leaving the Puttlam plant, Ruhunu Cement Works was privatised. The very man who did so much from scratch to profitability could not fathom the reasons for such a privatisation, and certainly could not come to terms with the government’s decision to privatise the plant.

When his mind goes back to the amount of struggle he did to transform a loss-making operation towards a profitable institution, he is still struggling to find answers to questions in his mind as to the rationale behind the government in privatizing a highly profitable organization, such as cement of all things, a complete 100 per cent.

Privatisation

By the time of privatising, according to his memory, Ruhunu Plant retrenched close upon 350 employees while 1,200 at Puttlam and 400 odd employees at Aruwakkuru. The privatisation has managed to get rid of a total of more than 75 per cent of employees. He would not accept the fact that there were excesses of members of staff at each plant, ( all plants made good profits) as the entire staff was looked after and were monetarily much better than any other government employees or he would rather say almost on par with private sector employees or above!

Ananda Karunarathne summarises the whole episode by saying that the panacea for selling public enterprises due to losses is not the answer. Losses take place totally due to mismanagement but nothing else. He throws up a challenge still, to take up any loss-making entity, with a promise to turn it into a profitable organization if only he is given a free hand without any political interference.

tilakfernando@gmail.com