Use existing resources for agri-food sector in Mahaweli areas

Posted on November 30th, 2022

By MAHINDA PANAPITIYA Irrigation Engineer who has worked for Mahaweli Project since 80s Courtesy The Island

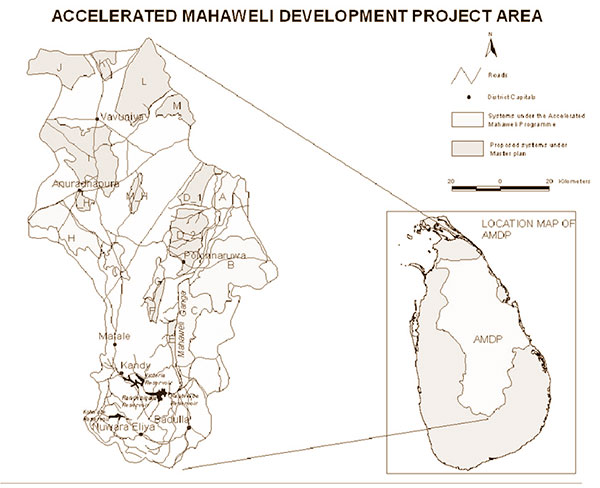

As originally planned, the present phase of the Mahaweli Project should be focused on social and economic development of the families settled in Mahaweli areas. It could be done by promoting food production in a sustainable way, to gain the return on investment of capital cost incurred on the infrastructure constructed for delivering water to fertile lands in the dry zone. The potential available in lands under Mahaweli Project, which cover about 1/3 of farming areas of the Dry Zone, could easily help the country to become self-sufficient in healthy foods, deviating from monotonous rice cultivation, provided it is managed with a right vision.

Concept

According to the concept explained below, there is a need to change the present management approach to a role focusing food production using limited water resources in the Dry Zone. For example, the term Block Manager” in the Mahaweli Management System was used during the construction phase in the 70s, because areas were blocked for the purpose of managing construction and settlement activities. There are five such blocks, each of about 3,000 Hectares, under Kalawewa Reservoir. Now the project is in the production phase. Therefore, the Block Managers appointed earlier should now be named as Regional Production Managers, because the very word BLOCK implies negative at the production phase.

The role of a Production Manager replacing Block Manage is a completely different discipline from what was adapted during the construction phase. In the current production phase, Irrigation projects should be perceived as a Food Producing Factory” – where water is the main raw material. A Production Manager’s focus should be to maximize food production, deviating from Rice Only Mode, to cater the market needs earning profits for farmers who are the owners of the factory”. Canal systems within the project area are just Belts” conveying raw materials (water) in a Typical Factory. Farm labor, fertilisers etc. are other inputs.

Required Management Shift

In order to implement the above management concept, there is a need for a paradigm shift at national level in managing large scale irrigation projects. In the new management paradigm, the farmers would be treated as clients, not the servants at the mercy of receiving water, according to rigid schedules decided by irrigation management staff. In this approach, the main purpose of managing irrigation systems is to deliver water to the farm gate at the right time in the right quantity.

It is also very pathetic to observe that main clients of irrigation projects (farmers) are now dying of various diseases caused by indiscriminate use of agro-chemicals. Therefore, there is a need to minimize the damages caused to the ecosystems where these food production factories are located. Therefore, the management objectives should also be focused on producing multiple types of organically grown crops, profitably without polluting the soil and groundwater aquifers.

Proposed Strategy

Existing Engineering staff should either be trained or new recruitments having Production Engineering background, should be made. Water should be perceived as the most limited input, which needs to be managed profitably with the farming community – jointly. Each Production Manager could be allocated a Fixed Volume of water annually, and their performance could be measured in terms of Rupees earned for the country per Unit Volume of water, while economically upgrading a healthy lifestyle of farmers. Staff of agencies such as Central Engineering Consultancy Burro (CECB), established in 80s at construction phase of the Mahaweli Project, can be trained to play the role of Production Engineering. CECB could be renamed as Central Food Production Burro (CFPB).

In addition to the government salary, the staff should also be compensated in the form of incentives, calculated in proportion to income generated by them from their management areas. It should be a Win-Win situation for both farmers as well as officers responsible for managing the food production factory. In other countries, the term used to measure their performance is $ earned per gallon of water to the country, without damaging the ecosystem. Another advantage of this approach is that the young generation of the farmers automatically get attracted to commercial agriculture because of high income generation.

Recent Efforts

We were able to introduce some of the concepts explained in this note during 2000 to 2004, under a program called Mahaweli Restructuring and Rehabilitation Project (MRRP) funded by the World Bank. It was done by operating the Distributary canals feeding each block as elongated Village Tanks. Recently we tried to modernize the same concept at Pilot Scale in System B, by independently arranging funds from ICTA. In that project, called Easy Water, we introduced an SMS communication system to the farmers, so that they can order water from the Maduru Oya Main Reservoir by sending a SMS, when they need rather; than depend on time tables decided by authorities as normally practiced.

Conclusion

The World Bank also recognised the above concept in 2003, as the best water management approach suitable for South Asian countries. Due to the lack of vision of existing managers in the irrigation sector focusing on food production, the above approach has not yet reaped the full benefits. What we need in Sri Lanka, is a political leadership to create challenges for irrigation officials to play a role of educated profit-oriented farmers, deviating them from Rice only mode, by promoting concepts similar to above. Also note that while I worked for a project in Azerbaijan funded by the International Fund for Agriculture Development, I was able to introduce the same concept and they are now using it successfully. I do not see any reason why we could not practice here.